Thiết bị thử nghiệm thép rơi cung cấp cấu trúc bền và hiệu suất liên tục trong phòng thí nghiệm thử nghiệm vật liệu

Mô tả sản phẩm

Máy kiểm tra tác động của trọng lượng rơi được thiết kế đặc biệt để kiểm tra hiệu suất tác động của ống nhựa, kim loại ván và các sản phẩm liên quan.Mục đích chính của nó là đánh giá chính xác tính chất chống va chạm của các vật liệu này, cung cấp dữ liệu quan trọng cho kiểm soát chất lượng và trình độ vật liệu.

Hệ thống điều khiển kết hợp công nghệ điều khiển kỹ thuật số tiên tiến, cho phép cài đặt tham số chính xác, hiệu chuẩn bằng không tự động và nâng và thả búa tự động.Thiết kế thông minh này không chỉ hợp lý hóa quy trình hoạt động mà còn loại bỏ hiệu quả các tác động thứ cấp - đảm bảo điều kiện thử nghiệm nhất quán và đáng tin cậy, kết quả lặp lại.

Tính năng của dụng cụ

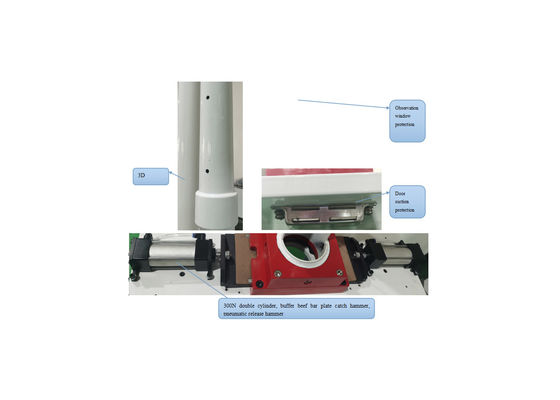

Hệ thống bảo vệ an toàn ba cấp

Máy thử được trang bị một cơ chế bảo vệ khóa nhiều lớp để đảm bảo an toàn hoạt động:

- Mức độ 1: Bảo vệ khóa cửa mẫu

- Mức độ 2: Bảo vệ cửa sổ quan sát

- Mức 3: Bảo vệ vị trí giới hạn trên và dưới

Hiệu suất nâng cao tốc độ

Được cung cấp bởi một động cơ bước mô-men xoắn lớn, máy thử nghiệm đạt được tốc độ nâng lên đến 250 mm / giây - cho phép búa đạt 2 mét từ 0 chỉ trong 8 giây.Điều này rút ngắn đáng kể chu kỳ thử nghiệm và cải thiện hiệu quả cho các kịch bản thử nghiệm thông suất cao.

Chức năng di chuyển thông minh

Tích hợp một thuật toán điều khiển tốc độ nhiều giai đoạn để đảm bảo giảm tốc bằng búa trơn tru và định vị chính xác với độ lệch bằng không.đảm bảo điều kiện thử nghiệm nhất quán và khả năng lặp lại dữ liệu đáng tin cậy.

3D mô hình thép rơi đường dẫn ống

Bơm hướng dẫn búa rơi được tối ưu hóa thông qua mô hình 3D, tích hợp lỗ ống xả để giảm thiểu sức kháng gió trong khi đáy búa - đảm bảo truyền lực va chạm ổn định.một cấu trúc tăng cường vòng tròn được thêm vào để ngăn chặn sự cố cấu trúc và biến dạng, tăng độ tin cậy hoạt động lâu dài trong môi trường thử nghiệm nghiêm ngặt.

Cơ chế nâng và thả búa khí nén

Phá bỏ các cơ chế búa điện từ truyền thống, người thử nghiệm áp dụng cấu hình khí nén mạnh để có hiệu suất vượt trội:

- Được trang bị xi lanh không khí kép dài 300N cho hoạt động mạnh mẽ, nhất quán

- Tính năng một bề mặt búa vải cao su để đảm bảo tác động ổn định, không gây hại cho các mẫu vật

- Thiết kế nâng / thả khí nén cơ bản loại bỏ các vấn đề như uốn cong cáp, vỡ dây và rò rỉ điện phổ biến trong hệ thống điện từ

- Tích hợp một hệ thống khóa tự động khí nén, cung cấp tăng cường an toàn và độ tin cậy hoạt động

Thiết kế lắp ráp tích hợp và mô-đun

- Cấu trúc cơ học: Sử dụng bộ lắp ráp hồ sơ hợp kim nhôm tiêu chuẩn hóa, đạt được tiêu chuẩn hóa quy trình, lắp đặt mô-đun và thiết kế nhẹ nhưng mạnh mẽ

- Hệ thống điện: Được cấu hình với màn hình cảm ứng 7 inch và Delta PLC, đảm bảo hoạt động trực quan, hiệu suất ổn định và bảo trì thuận tiện

Các thông số kỹ thuật

| Mô hình |

XJL-300D |

| Nhiệt độ môi trường |

10°C-35°C |

| Chất lượng búa thả |

0.25kg-10kg, 0,125Kg/mỗi lần gia tăng |

| Chiều kính của búa |

D25mm,D90mm |

| Chiều cao của sự sụp đổ |

40mm-2000mm, lỗi ≤ ± 2mm |

| Chiều kính của mẫu |

Φ10mm-Φ450mm |

| Sự lệch của trung tâm va chạm từ trung tâm vật cố định |

≤2mm |

| V-type hỗ trợ |

120° |

| nguồn |

220VAC ± 10% |

| Kích thước phác thảo |

730mm × 700mm × 3650mm |

| Trọng lượng ròng |

300kg |

Chức năng chính

Thử nghiệm tác động bằng búa rơi là một dụng cụ thử nghiệm chính xác được công nhận rộng rãi được thiết kế đặc biệt để đánh giá sức mạnh tác động bên ngoài của ống nhựa, tấm nhựa,và vật liệu phi kim loạiNó là một công cụ quan trọng để đánh giá hiệu suất, kiểm soát chất lượng và trình độ vật liệu trong ngành công nghiệp nhựa, xây dựng và sản xuất.

Đối với ống nhựa, bộ kiểm tra cung cấp phạm vi kiểm tra va chạm toàn diện cho một loạt các sản phẩm, bao gồm nhưng không giới hạn ở: ống nước PVC-U, ống nước áp suất thấp,ống bọt lớp lõi, đường ống sóng hai bức tường, đường ống Carat, đường ống thép được cột thép tăng cường, đường ống nước PE, đường ống điện MPP, đường ống xoắn tường rỗng và đường ống điện CPVC.

Nguyên tắc

Đối với các quy trình sản xuất sản xuất hàng loạt hoặc ép liên tục, the tester enables the determination of the product's True Impact Rate (TIR) by impacting the specified area of test specimens with a drop hammer of predefined mass and dimensions from a designated height.

Phương pháp thử nghiệm này cung cấp tính linh hoạt đặc biệt để đáp ứng các yêu cầu kỹ thuật của các sản phẩm khác nhau - đạt được bằng cách điều chỉnh khối lượng búa thả, chiều cao va chạm hoặc cả hai tham số.

Theo các giao thức thử nghiệm tiêu chuẩn, giá trị TIR tối đa được chỉ định là 10%.

Hỗ trợ và Dịch vụ

Để đáp ứng các yêu cầu ứng dụng độc đáo của bạn, chúng tôi cũng cung cấp các giải pháp kỹ thuật tùy chỉnh phù hợp với các kịch bản thử nghiệm cụ thể, loại vật liệu và mục tiêu hoạt động của bạn.Cho dù bạn cần tối ưu hóa tham số, nâng cấp phụ kiện, hoặc thích nghi quy trình, nhóm của chúng tôi tận dụng chuyên môn của ngành để cung cấp hỗ trợ được nhắm mục tiêu.

Chúng tôi cam kết cung cấp dịch vụ khách hàng và hỗ trợ kỹ thuật hàng đầu trong ngành. Nhóm hỗ trợ đáp ứng của chúng tôi có sẵn 24/7 để nhanh chóng giải quyết bất kỳ câu hỏi kỹ thuật, mối quan tâm hoạt động,hoặc các yêu cầu dịch vụ khẩn cấp - giảm thiểu thời gian ngừng hoạt động và tối đa hóa năng suất của thiết bị.

Chúng tôi mời bạn liên hệ với nhóm của chúng tôi sớm nhất có thể để biết thêm chi tiết, tư vấn cá nhân hoặc thảo luận về nhu cầu hỗ trợ cụ thể của bạn.

Câu hỏi thường gặp

Q1: Thiết bị thử nghiệm búa thả là gì?

A1: Thiết bị thử nghiệm búa rơi là một dụng cụ thử nghiệm va chạm chính xác được sản xuất bởi JHH với cơ sở sản xuất tại Bắc Kinh, Trung Quốc.Nó được thiết kế đặc biệt để đánh giá khả năng chống va chạm của vật liệu và sản phẩm - một chỉ số hiệu suất thiết yếu cho đánh giá tính toàn vẹn cấu trúc.

Q2: Mục đích chính của thiết bị thử nghiệm búa thả là gì?

A2: Mục đích chính của Thiết bị thử nghiệm búa thả là đo chính xác khả năng chống va chạm của các đối tượng mục tiêu, cung cấp dữ liệu quan trọng để hỗ trợ xác minh chất lượng sản phẩm,kiểm soát chất lượng, và đảm bảo độ tin cậy trong sản xuất và các ứng dụng công nghiệp.

Q3: Những sản phẩm/vật liệu nào tương thích với Thiết bị thử nghiệm Thủy đập?

A3: Thiết bị có thể áp dụng cho một loạt các đường ống (bao gồm nhưng không giới hạn ở đường ống nước PVC-U, đường ống nước thải, đường ống nước áp thấp, đường ống truyền áp thấp,ống bọt lớp lõi, ống sóng hai bức tường, và ống nước PE) và cũng hoàn toàn tương thích với tấm nhựa cứng.

Q4: Độ chính xác đo của Thiết bị thử nghiệm búa thả là bao nhiêu?

A4: Thiết bị thử nghiệm búa rơi có độ chính xác đo lường cao là ± 0,5%, đảm bảo kết quả thử nghiệm đáng tin cậy, lặp lại đáp ứng các yêu cầu tiêu chuẩn thử nghiệm quốc tế.

Q5: Năng lượng thử nghiệm tối đa của Thiết bị thử nghiệm búa thả là bao nhiêu?

A5: Thiết bị cung cấp năng lượng thử nghiệm tối đa là 300 J, bao gồm các yêu cầu thử nghiệm va chạm của hầu hết các ống công nghiệp và các sản phẩm nhựa cứng.